The fabrication work flow merged hand-crafted steam bending with augmented reality construction techniques such as 3D laser projection and photo laser scanning. The Architect developed scripting techniques to provide layouts of over 100,000 linear feet of oak millwork slat center lines to The Fabricator. The construction plans called for more than 200 customized panels representing nine design types, each type formulated to meet strict acoustic requirements.

- Open story

The fabrication work flow merged hand-crafted steam bending with augmented reality construction techniques such as 3D laser projection and photo laser scanning. The Architect developed scripting techniques to provide layouts of over 100,000 linear feet of oak millwork slat center lines to The Fabricator. The construction plans called for more than 200 customized panels representing nine design types, each type formulated to meet strict acoustic requirements.

- Open story

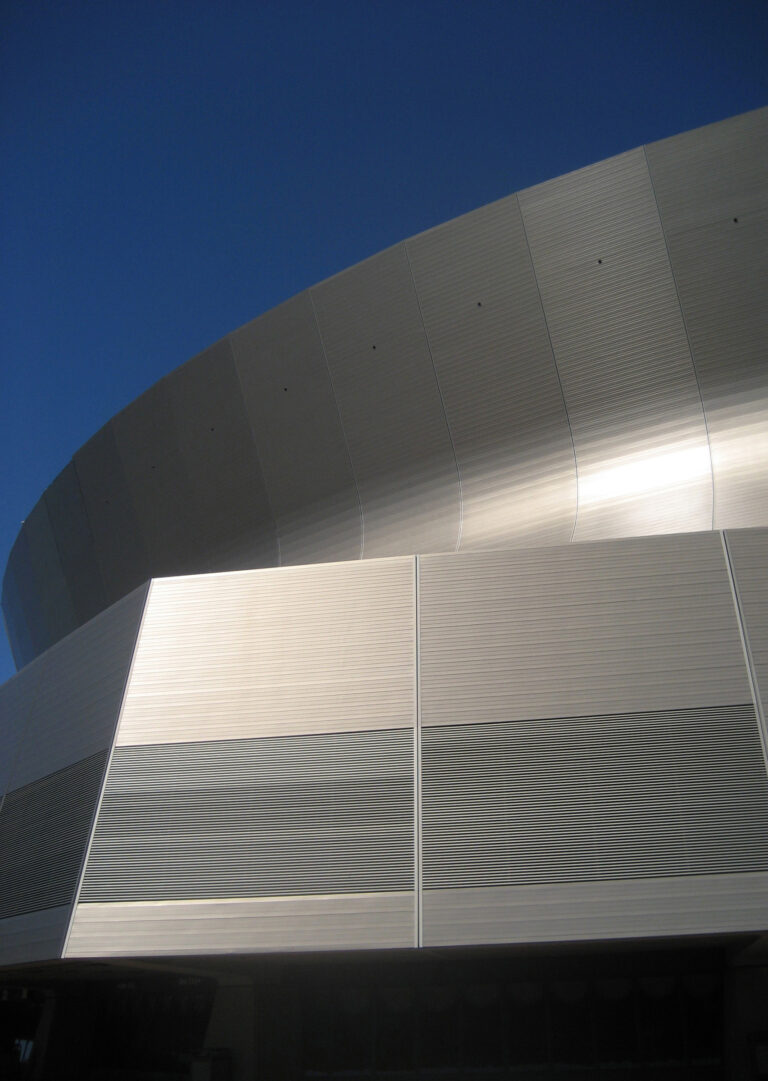

As specialty design consultants to the cast-stone panel fabricator, Advanced Cast Stone, Case and Method Design working with David Kufferman, P.E., developed and engineered a sophisticated structural steel support system that secures the 1,150 unique stone panels, each with its own set of customized connections. Key to process was the programming environment of Grasshopper, Karamba and Geometry Gym, operated in parallel with Robot structural analysis software and SDS/2 for steel detailing. The end result was a fully detailed (LOD 400) model of every structural member, support and connection used ultimately for fabrication and installation of the steel supports and cast stone connections.

- Open story

As specialty design consultants to the cast-stone panel fabricator, Advanced Cast Stone, Case and Method Design working with David Kufferman, P.E., developed and engineered a sophisticated structural steel support system that secures the 1,150 unique stone panels, each with its own set of customized connections. Key to process was the programming environment of Grasshopper, Karamba and Geometry Gym, operated in parallel with Robot structural analysis software and SDS/2 for steel detailing. The end result was a fully detailed (LOD 400) model of every structural member, support and connection used ultimately for fabrication and installation of the steel supports and cast stone connections.

- Open story

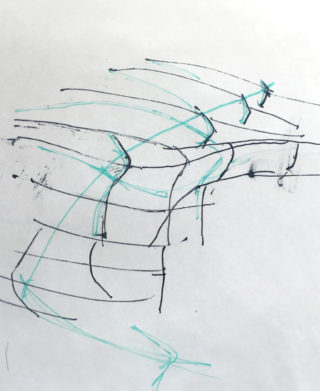

During the design phase for the Alliance Theatre Transformation, Trahan embarked on an artistic collaboration with renowned sculptor Matthias Pliessnig. This process elevated the shaping and tectonics of the chamber and lobby. The steam bending process perfected by Matthias allowed the architect to combine the precise digital modeling required by the acoustician, with the craftsmanship and beauty of the design vision. This collaborative process produced acoustically tuned forms that amplifies the artistry performed on the stage.

- Open story

During the design phase for the Alliance Theatre Transformation, Trahan embarked on an artistic collaboration with renowned sculptor Matthias Pliessnig. This process elevated the shaping and tectonics of the chamber and lobby. The steam bending process perfected by Matthias allowed the architect to combine the precise digital modeling required by the acoustician, with the craftsmanship and beauty of the design vision. This collaborative process produced acoustically tuned forms that amplifies the artistry performed on the stage.

- Open story

Inspired by the quiet transformation of natural patinas, the Performance Pavilion at Luther George Park is an exploration of artistry, materiality, and openness. It envisions the architecture as a living infrastructure that evolves with time. Through hand torqued weathering steel, fabricated by CIG, the pavilion becomes a historical canvas that records and absorbs the passage of time, and human presence.

- Open story

Inspired by the quiet transformation of natural patinas, the Performance Pavilion at Luther George Park is an exploration of artistry, materiality, and openness. It envisions the architecture as a living infrastructure that evolves with time. Through hand torqued weathering steel, fabricated by CIG, the pavilion becomes a historical canvas that records and absorbs the passage of time, and human presence.

- Open story